Spark Machinery produces machines to process moving film.

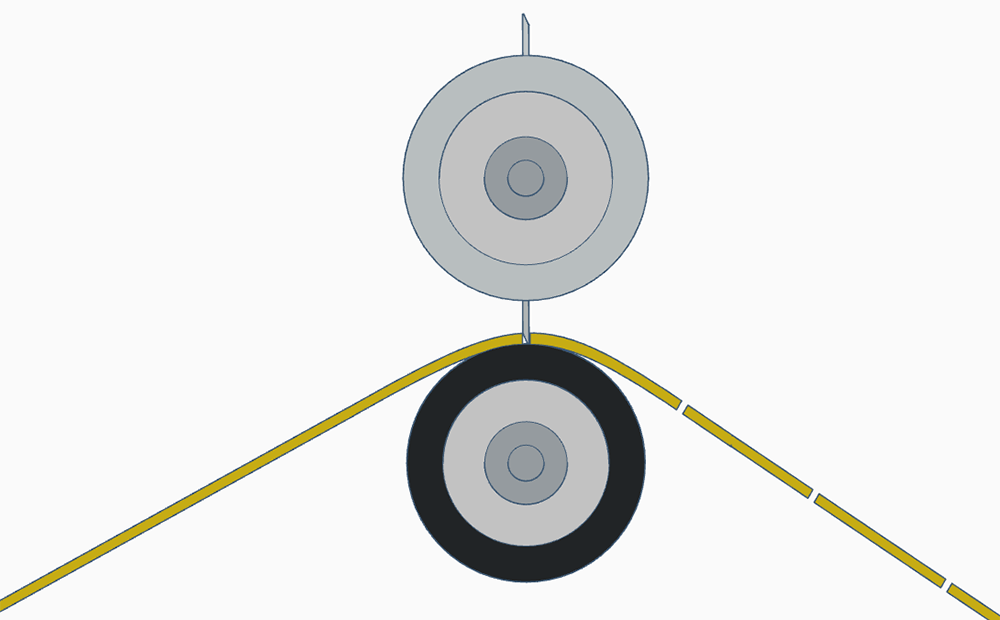

Machines and their parts to punch holes on plain or printed film. They have to be integrated into existing machinery such as extruders, slitters, bag machines etc.

Ideal for holes in fruit and vegetable bags, shopping bags, bags for flowers, in mulching, agricultural, food and electronic packaging, etc.

Select this

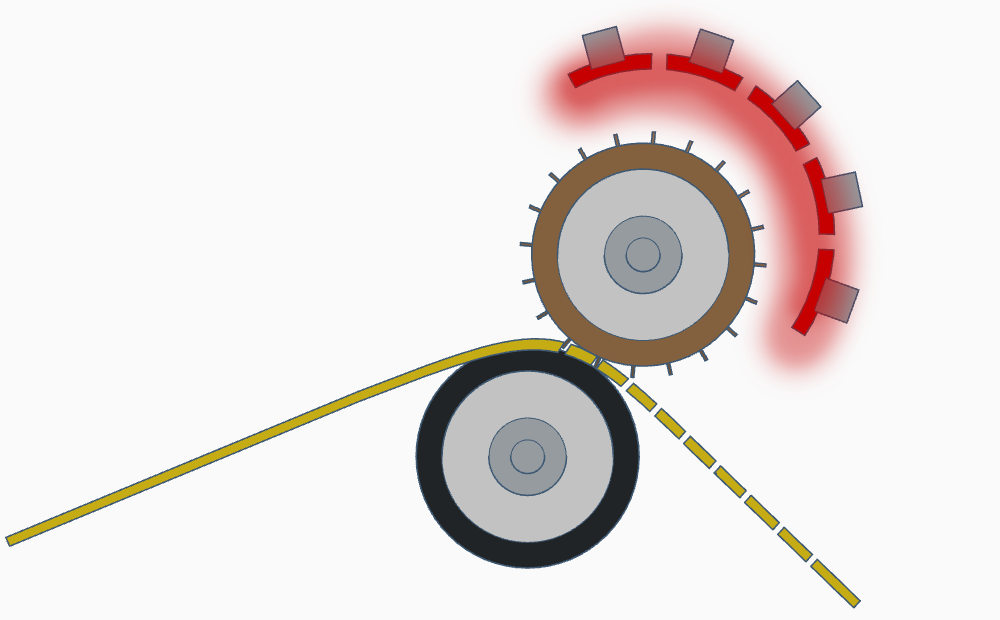

Machines and their parts to punch micro holes on plain or printed film, using hot needles. They are designed to control permeability and have to be integrated into existing machinery such as extruders, slitters, welding machines, etc.

They are ideal for processing shrink film and mono or bi-oriented materials with any density of needles per cm2; for punching holes on packaging for fruit and vegetables and for grain and feed; for making holes on bread bags, corrugated plastic (PP, PE), coffee and tea filters, packaging and bags in which it is necessary to check permeability, packs for products that require post-packaging treatments (e.g. sterilization, cooling, etc.), plasters, diapers, adhesives etc.

Select this

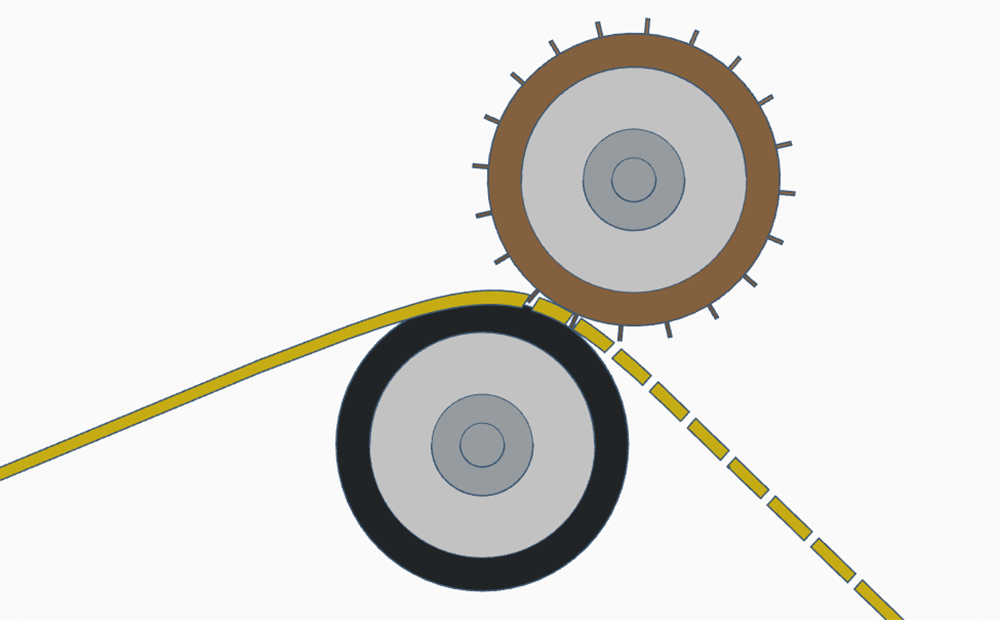

Machines and their parts to punch micro holes on plain or printed film, using cold needles. They are designed to control permeability and have to be integrated into existing machinery such as extruders, slitters, welding machines, etc.

They are ideal for punching holes on vegetable and fruit bags and on packs for electronic objects and products that require post-packaging treatments (e.g. sterilization, cooling, etc.); for making holes on breathable film for those packages or bags in which it is necessary to check permeability and for providing acoustic-thermal insulation.

Select this

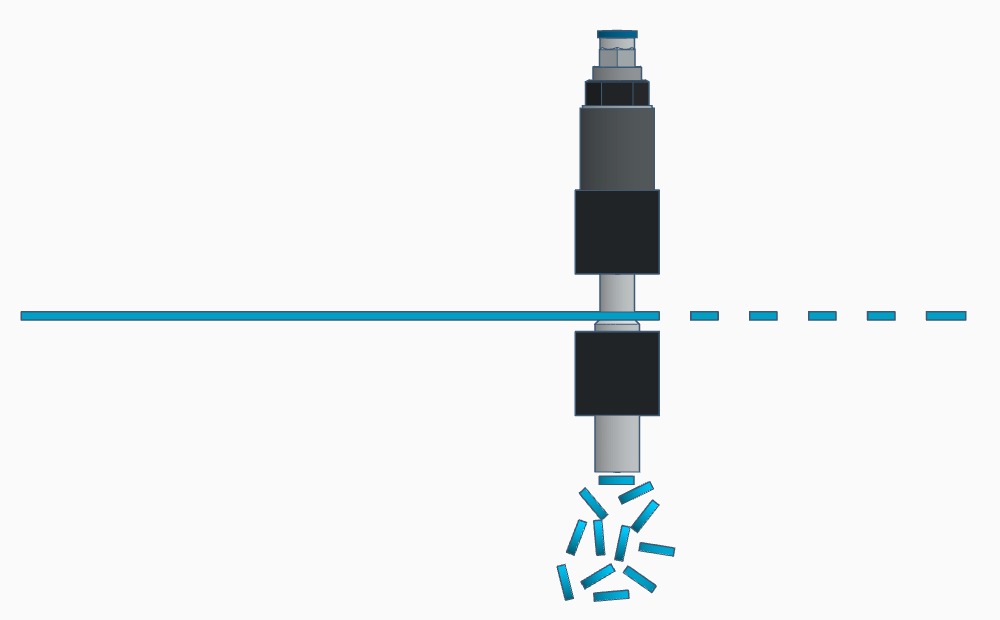

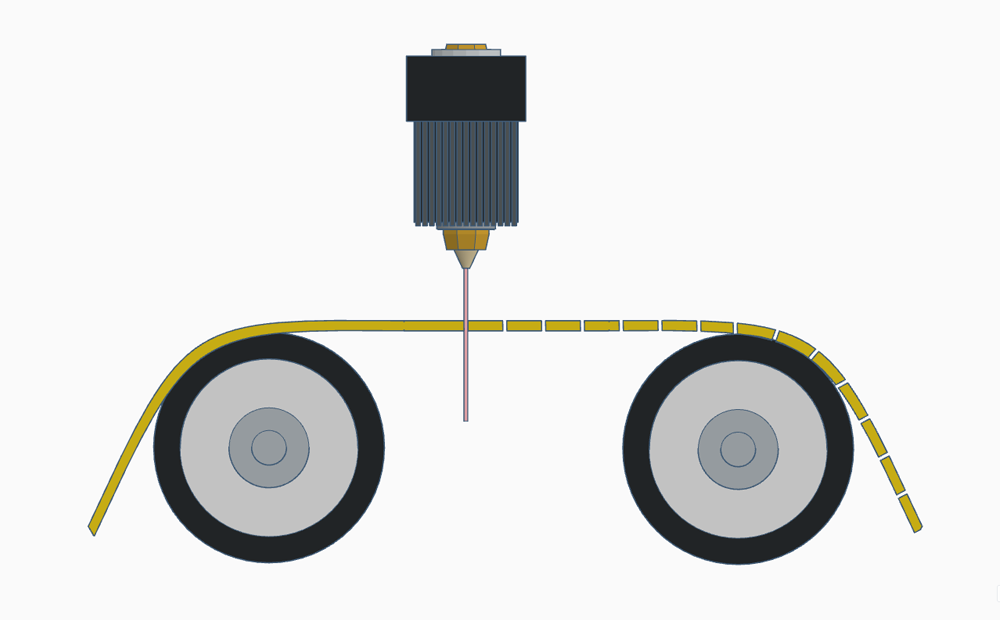

Machines and their parts to create micro holes or scoring on moving material, to be integrated in the line of extruders, welders, cutters, etc.

Suitable for increasing the shelf life of fresh products, thus controlling the exchange of air between the package and the outside. Also ideal for making pre-cuts for easy opening.

Select this

Machines and their parts to crosscut plain or printed film. They have to be integrated into existing machinery such as extruders, slitters, bag machines etc.

For easy tear-off reels, pre-cut reels, non-woven materials, reams of paper, single-use placemats, labels and adhesive labels, garbage bags etc.

Select this